One Revolution or Two

The Counterpoise engine does in one revolution of the crankshaft what the Otto cycle engine does in two. Each piston fires in 360 degrees of the crankshaft. Because of this a 4 cylinder Counterpoise engine can replace an 8 cylinder Otto Cycle engine. The results of this would be about half the weight and half the parts with improved performance!

A Longer Stroke

The offset bore angle of the Counterpoise engine allows the stroke of the piston to follow what would be the hypotenuse or the longest side of the triangle distance between the center of the crank and the top of the bore. This longer distance means a longer stroke for a given crankshaft. This would result in a mechanical advantage caused by the piston moving a greater distance to rotate the crankshaft.

More Than 180 Degree Advantage

Our piston being on an angle as it travels the stroke of the engine, means that at Botton Dead Center (BDC) of the stroke, it is off to the side of the center of the engine. In addition to the advantage of the bore being on an angle, the crankshaft is driven further than the 180 degree of an Otto cycle to Bottom Dead Center. This will result in additional degrees of rotational power delivered to the crankshaft.

A Cooler Exhaust

Due to the piston having more than the 180 degree rotation like a standard engine. The air-fuel mixture has a few degrees more rotational time to cool in the combustion chamber. A basic understanding of this fact is a cooler exhaust means more work was taken from the fuel in the Counterpoise Cycle than in the Otto Cycle. This means there is better use of the fuel. It was burned more completely, having lower emissions.

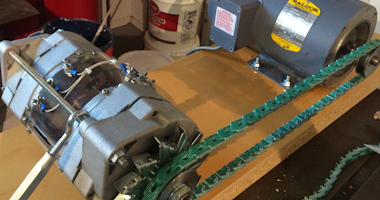

Two Surfaces are Better Than One

In our engine, force on the top of the piston is used as in the Otto Cycle engine, however, that same force is pushing on the ceiling of the bore in both. In the Otto Cycle engine the ceiling of the bore is a "dead Head", meaning it doesn't move, it just gets hot. In the Counterpoise Engine the head is on a rotational assembly and at an angle that allows the force on the head to push the assembly in the correct direction to aid in the torque output of the engine. This means, you have two surfaces rather than one being pushed by the expanding fuel mixture.

Double the Torque with Half the Cylinders

In an Otto Cycle engine the piston rod generally pushes on the crankshaft somewhere around 2 inches* from the center of the crankshaft. This results in additional output torque of the engine. In the Counterpoise engine, the ceiling of the bore is also forced to move by the pressure. The ceiling of our bore is about 12 inches* from the center of rotation (crank) a much longer lever to rotate. The torque produced by the rotating bore assembly is greater than the torque produced by the crankshaft alone. The combined torque is therefore better than doubled and this is achieved with only half as many cylinders.

*Varies based on scale of engine.

All of the Above and More

Due to the advantages we have just discussed, the counterpoise engine does not have the disadvantage of having to fire the spark before top dead center. Instead the spark is fired at top dead center. This gives our engine 100% use of the power stroke. With these benefits it can be seen that the larger this engine is, the longer the lever for the bore assembly and the greater the torque. This makes the multi-fuel Counterpoise engine much more capable of using various fuels like natural gas, propane, DME, bio-diesel, renewable green hydrocarbons, and potentially even green hydrogen. This would mean we can use cleaner burning fuels in high torque engines.